Last updated on

Explore the engaging world of live steam because its unique appeal can transform your home into an unforgettable space.

Live steam is a fascinating hobby where enthusiasts get to build and operate miniature trains running on real steam power. These replicas, striking in their detail and functionality, make you feel like a true conductor and immerse you in the world of traditional railroading.

Engaging with live steam not only involves crafting your steam-powered marvel, but also understanding steam mechanics, safe operating principles, and maintenance practices. Covering all these aspects, this article offers insights into every aspect of live steam, from model selection and assembly to operative techniques and safety measures, providing an ultimate guide for anyone who dreams of having their own miniature steam railway.

Key takeaways:

- Live steam is a hobby where enthusiasts build and operate miniature trains powered by real steam.

- Understanding live steam technology involves knowing the fuel source, heated water, piston movement, and exhaust.

- The components of a live steam engine include the boiler, piston and cylinder, valves, firebox, smokebox, and steam dome.

- Live steam models offer authenticity, while diesel models are easier to use and maintain.

- Building a live steam engine requires precision, materials selection, machining skills, systematic assembly, and attention to safety measures.

Understanding Live Steam Technology

Live steam technology operates on the principle of heating water to create steam, which powers mechanical devices, often replicated in smaller scale models like trains. To grasp its functioning, consider the following points:

- Fuel Source: Whether it’s electricity, coal, or other fuels, this energy is fundamental to heat the water.

- Heated Water: The fuel energy heats the water inside a boiler. The boil transforms the water into steam.

- Piston Movement: The pressurized steam then drives pistons. Their movement converts the thermal energy into mechanical energy.

- Exhaust: Post piston movement, the steam exhausts out, lowering the pressure, allowing the piston to return for the next cycle.

Understanding each step in this cycle is key to grasping live steam technology and the intricate workings of miniature locomotives.

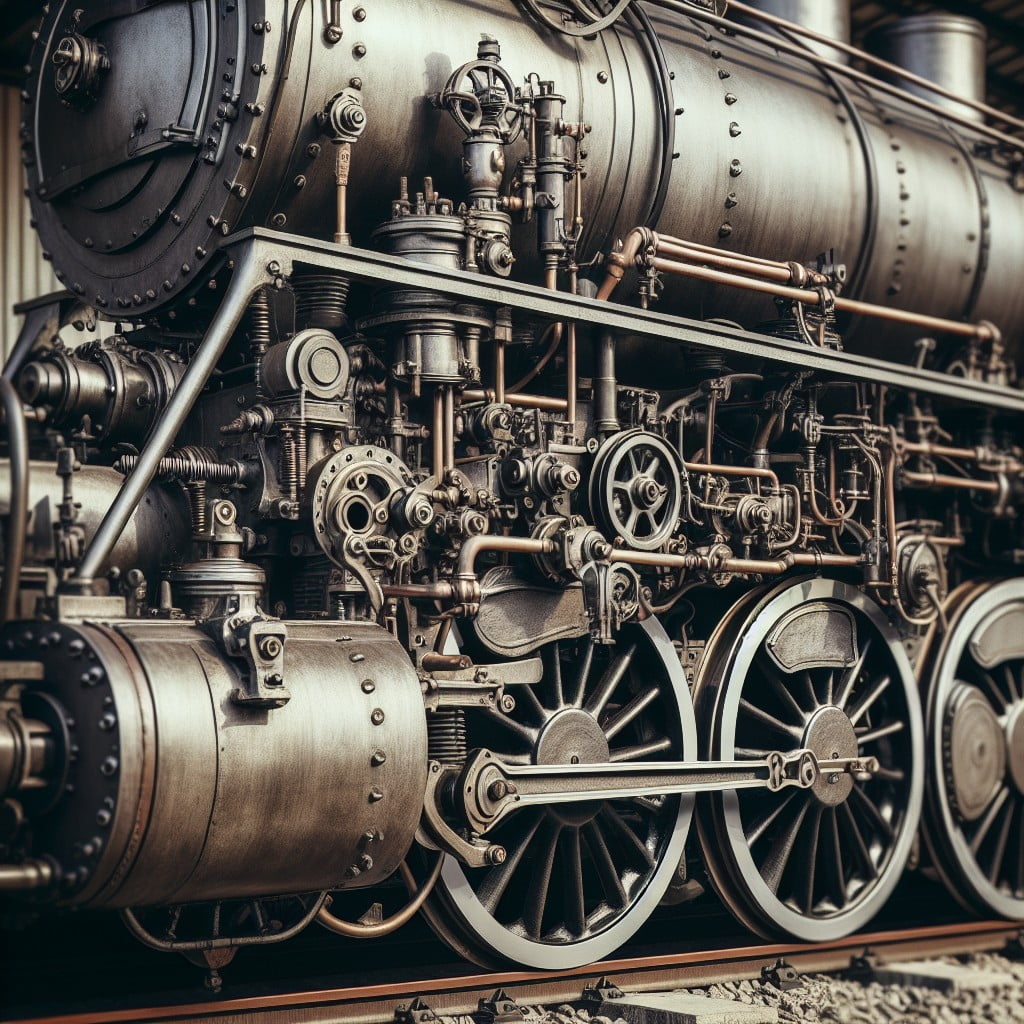

Components of a Live Steam Engine

The typical Live Steam engine is composed of a few critical components:

- Boiler: The heart of the engine, where water is heated to produce steam.

- Piston and Cylinder: Harnessed steam pushes the piston, that in turn propels the engine.

- Valves: Used to control steam flow, ensuring efficient operation of the model.

- Firebox: The area where actual burning occurs, heating the boiler.

- Smokebox: Collects and expels exhaust gases, also contributing to the draw of air for combustion in the firebox.

- Steam Dome: Contains the regulator to provide an even flow of steam to the cylinders.

Understanding each component’s function is vital in maintaining the model, ensuring its smooth operation, and troubleshooting any issues that may arise.

Basic Principles of Steam Generation in Model Trains

Harnessing the power of steam involves a process where water is heated to form steam and this steam is used to power an engine. Here’s how it works in a simple model train context:

1. Heat Source: Typically fueled by coal, gas, or an electric element, this source heats water contained in a boiler.

2. Water Conversion: The boiler’s heat turns the water into steam. It is here that potential energy is converted into kinetic energy.

3. Piston Drive: The steam engine has a cylinder and piston arrangement, just like a car. The pressurized steam pushes the piston, which, in turn, drives the engine’s wheels.

4. Control: A throttle valve allows adjustment of the steam supply to control the speed of the model train.

5. Excess Steam Release: The steam needs to be exhausted after utilisation, which usually happens through the funnel or chimney, keeping the cycle going.

6. Water Refill: Ships and stations along the model train’s route provide water refill stations, maintaining a sufficient water supply in the boiler.

Remember, while a scaled-down version, steam model trains work on the same fundamental principles as their full-size counterparts. With that insight, you’re more equipped to tackle live steam model railroading!

Live Steam Vs Diesel Model Railroading

When comparing steam and diesel model railroading, several key differences emerge. Live steam models, for one, boast an impressive authenticity, recreating the sights, sounds, and even smell of a full-sized steam locomotive. Their charm lies in the miniaturization of complex mechanics, where feeding the boiler and adjusting the throttle mirror the operation of their real-life counterparts.

On the other hand, diesel models, while not offering the mechanical interaction of steam engines, can yield a host of benefits. They are generally easier to use, maintain, and run, making them a more accessible option for newcomers to the hobby. Without the need to manage steam pressure carefully, enthusiasts can focus on aspects like optimizing control settings or designing their routes.

Therefore, the choice between live steam and diesel fundamentally comes down to personal preference. If you value replicating the intricate workings of a steam engine, live steam models deliver an unmatched experience. However, if ease of use and ease of maintenance rank high on your list, diesel models certainly warrant serious consideration.

How to Build a Live Steam Engine Model

In constructing a live steam engine, precision is of utmost importance. Begin with a plan, which will guide you through the process. It is important to select a design suited to your skills and tools. Simple designs are preferable for beginners – those with working parts that can easily be manufactured at home. Gradually, you might want to tackle more complex designs.

Materials selection is critical. Brass and copper are ideal for boiler components due to their superior heat conductivity and resistance to corrosion. Consider steel for the frame because of its solidity and durability.

Mastering the machining process is a fundamental part of building your model. This involves cutting, drilling, and turning metal pieces. Invest time in learning to use a lathe, drill press, and milling machine, as these are crucial tools in fabricating small engine parts. Remember, precision is key.

When assembling, work systematically. Start with the locomotive frame, moving on to the wheels and gears. The boiler should always be considered last.

Lastly, safety measures must not be underestimated. Regularly inspect for leaks to avoid dangerous situations. Always ensure correct and secure assembly of all parts – remember, you’re dealing with steam under pressure.

Remember, patience is as vital as precision. Building a live steam engine isn’t a race. Take the time to enjoy every step of this rewarding journey.

Maintenance and Safety Measures for Live Steam Models

Reliable operation of your live steam model hinges greatly on regular maintenance. This upkeep should include clearing the fire-tube, boiler, and pistons from soot and sediment buildup. Regular inspections for leaks or wear and tear are critical to ensure smooth and safe functioning. Don’t forget to appease the thirst of your steam-driven model; keeping the boiler adequately filled with distilled water tremendously boosts its lifespan.

Play it safe when handling live steam. Employ gloves and safety glasses during operation to protect your skin and eyes from accidental scalds or steam bursts. Remember, the locomotive can become as hot as a real steam engine. Hence, allowing the model to cool before handling prevents burns.

Most importantly, care in the transportation and storage of your model pays in longevity. Always disconnect fuel sources when relocating your live steam model, and ensure it is sheltered from dampness or extreme temperatures when storing.

In essence, preventing hazards and ensuring longevity are twin fruits of a well-maintained live steam model. Devotion to these principles will ensure countless hours of enjoyment in steam technology exploration.

Building a Shipping Crate for Large-Scale Live Steam Trains

When it comes to the construction of a shipping crate for your grand-scale steam model, certain steps need to be incorporated precisely.

1. Material Selection: First and foremost, the materials used for the crate should be sturdy and heavy-duty to protect your valuable model. A combination of plywood sheets for the core structure, combined with L-brackets for additional strength, is commonly used.

2. Size Measurements: Ensure you size the crate appropriately. Measure the width, length, and height of the train to avoid the model moving inside the crate during transport.

3. Padding Material: Use foam padding or bubble wrap to mitigate any possible damage from potential impacts during transit. It’s crucial to pad both around and beneath the model for full coverage.

4. Accessibility: Don’t overlook how you’ll remove the model from the crate. Design the crate with removable sides or a hinged lid.

5. Divide Into Sections: If the model is large, consider dividing the crate into multiple sections, each containing a different part of the train.

Remember, budgeting for a high-quality crate is an investment essential to protect your large-scale live steam train during transport.

Converting a Model Train Car Into a Live Steam Sized Car

As you embark on the conversion process, there are several considerations to bear in mind. First, bear in mind that scale is crucial; the model train car should adhere to the proportions of its full-sized counterepart. This not only ensures aesthetic accuracy but also contributes to the authenticity of the operational aspects.

Next, consider the materials required which include a sturdy base, tiny screws, and precisely designed steam engine components. Resist the temptation to compromise on quality for cost-saving, as this could lead to performance deficiencies later on.

Building skills are essential in this process. Detailed work such as mounting trucks, crafting couplers, and constructing appropriate brake gear can be challenging without a familiarity with model construction.

Finally, remember to take account of weight. A fully-loaded model train car potentially has to haul a sizable cargo, and the’s steam engine must be robust enough to handle this. Lighter isn’t always better in the world of live steam – you need to find the right balance.

Overall, transforming a model train car into a live steam sized car is a careful balance of precise construction, replication of detail, and selection of the right materials and components — an exciting project for any steam enthusiast.

Overview of Live Steam Model Train Events

Several large events throughout the year allow live steam enthusiasts to gather and share their passion. These meetings often feature model exhibitions where artisans showcase their finely detailed creations, ranging from faithful miniature replicas of historic trains to imaginative steampunk designs.

Interactivity is a key component of these gatherings. Visitors can observe these scale models in action on miniature railways, offering a tangible representation of steam technology. Some events invite attendees to take control and test drive the models on offer, providing hands-on experience.

Education also forms a core part of these occasions. Activities often include workshops, showcasing building and maintenance techniques, safety processes, and history lessons on the development and use of steam power.

Additionally, special events such as auctions or swap meets allow attendees to purchase model components or even whole trains, from raw materials to finished models.

While dates and specifics vary each year, some notable occurrences include the North American Model Engineering Exhibition, International Small Scale Steamup, and the Diamondhead International Steam Meet. Each presents its own unique flavor and opportunities, making them worthwhile additions to any live steam aficionado calendar.

Exploring Live Steam Forums and Communities

For enthusiasts, more enjoyment often arises from sharing, discussing, and learning from others in the hobby. Various forums and communities exist both online and offline that cater to the live steam model train niche. Some offer advice on building, maintaining, and operating live steam models.

Online forums like The Home Machinist and The Live Steamers are treasure troves of knowledge. Members range from beginners seeking advice to seasoned experts sharing intricate projects. Remember to adhere to each forum’s etiquette rules when posting inquiries or responses.

Local communities, such as model railroad clubs, are also excellent sources of information. They often host events, workshops, and group build sessions. Seek such clubs within your locale for a hands-on approach to learning.

Social media groups on platforms such as Facebook, Instagram, and YouTube allow users to share images or videos of their models and give advice on various aspects.

The key point is to seek appropriate channels that match your needs and level of expertise. This environment of sharing and learning greatly adds to the overall live steam model train experience.

Deciphering the Jargon: A Live Steam Glossary

When delving into the world of live steam, it’s essential to get familiar with specific terminology. Hence, shedding light on a handful of commonly-used phrases:

1. Cab: This is the driver’s section in a train where the controls and instruments reside.

2. Boiler: A pressure vessel that produces steam. It’s a critical part of a steam engine.

3. Gauge: Refers to the distance between the rails on a railway track. For live steam, this could be anything from 3.5″ to 7.5″.

4. Tender: This is a vehicle towed behind a steam locomotive which carries necessary supplies like fuel and water.

5. Scale: The ratio between the size of a model and the real, full-sized equivalent.

6. Piston: A cylindrical component that moves under the pressure of steam within the engine, driving the locomotive.

7. Coupling Rod: This connects driving wheels together, allowing power to be transferred.

8. Regulator: Also known as the throttle, this controls the engine’s power by regulating the amount of steam sent to the cylinders.

Equipping yourself with this knowledge will make discussions more meaningful and enhance your live steam experience.

How to Find Local and Online Live Steam Clubs

Scouring the internet is one of the easiest ways to locate a live steam club. Websites like discoverlivesteam.com act as great databases, listing clubs around the world. Social media platforms like Facebook and Instagram can also be handy for finding groups dedicated to live steam enthusiasts.

Visit model train stores and hobby shops in your area. Many of such places have connections with local clubs and can guide you to the one best suited for your interests.

Industry events and exhibitions, often held at fairgrounds or convention centers, can also provide pathways to local clubs. Keep an eye on the event calendars of these venues.

Online forums and communities, such as the ones on model-railroad-hobbyist.com or therailwire.net, also act as excellent networking avenues. There are many threads dedicated to discussions about live steam clubs.

Remember, joining a club is not merely about finding people with common interests, it’s about sharing knowledge, ideas, and experiences in maintaining and operating live steam models.

Discover Live Steam’s Position in the Market

Touted as the premier platform in the Live Steam train hobbyist community, Discover Live Steam not only provides access to a bevy of resources, but also leaves a significant imprint on its market sector. The company stands out for its range of product offerings from full-scale models to miniature replicas, expanding its reach to various hobbyist levels.

Its uniquely tailored services are designed to captivate passionate enthusiasts and draw in curious beginners. Through its classified ads, the company offers a bustling marketplace for buying, selling, and trading hobby-related items, effectively injecting liquidity into this niche segment.

Additionally, Discover Live Steam extends beyond transactional operations. It serves as a vibrant hub for information exchange and community building. Its comprehensive list of clubs and events fosters connectivity among steam enthusiasts worldwide.

The company has thus positioned itself not just as a platform, but as an essential, all-encompassing orbit for this tight-knit community, reaffirming its authority and influence within avid Live Steam hobbyist circles.

Taking a Glimpse At Discover Live Steam’s Top Competitors

The market for live steam has a competitive landscape, providing several choices for hobbyists and enthusiasts. Clubs, forums, and manufacturers around the country compete in terms of services, community involvement, product quality, and technological innovation.

Roundhouse Engineering is recognized for its range of finely detailed, ready-to-run models. These engines are designed for the robustness required in the garden railway world while maintaining the high detail seen in smaller models.

Aster Hobby Co., in contrast, offers its products in kit form, allowing enthusiasts the unique experience of assembling their own detailed and functional steam engine. With a customer base spread across the globe, they have a reputation for their high-quality products and precise machining.

Maxitrak stands out for their “ride-on” scale model railroads – bridging the gap between smaller models and full-sized railway trains. Besides developing their own extensive range of models, they also supply a comprehensive range of narrow gauge products and services.

Mamod stands as a legacy brand, having introduced steam engines as educational toys since the 1930s, and today continues to manufacture a range of model steam engines, vehicles, and constructions kits.

These competitors lead the market through constant innovation and their unique approaches to fostering the love for live steam. They each offer a different experience, providing a vast variety for enthusiasts of all levels of expertise in this fascinating activity.

Understanding Steam Technology in Context: The Top Companies in the United States

Several prominent companies make significant contributions to the United States steam technology industry. Each offering unique, well-engineered products, these firms are testament to the enduring importance of this technology.

Accucraft Trains, founded in 1994 in Mountain View, California, stands as a leader in manufacturing model trains and accessories. Their expansive product range includes a variety of scales and gauges, with live steam models as a notable addition.

Aster Hobby Co., established in Japan, but maintains a noticeable presence in the U.S market. They offer precision model live steam locomotives that have earned a reputable place in the industry.

Bowman Models is a historical company that laid many foundations for steam technology. Despite ceasing operations in the 1940s, their impact persists in today’s market.

Lastly, Roundhouse Engineering Co. based in Doncaster, England, has a strong U.S clientele. They offer affordable, high-quality live steam locomotives, suitable for beginners and experienced live steam enthusiasts alike.

An understanding of these companies gives an insightful context to the thriving industry of live steam technology within the United States. Each entity brings distinctive value, enriching the field with diversity and innovation.

Recap: